Hazard Communication

Many chemicals used in research at the University of Florida pose a wide range of health and physical hazards. Before using any chemical, it is important to understand what the hazards may be and how to work with it safely. Always review the UF’s General Chemical Hygiene prior to beginning any work with hazardous chemicals.

Globally Harmonized System

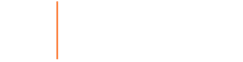

The Globally Harmonized System (GHS) of the Classification and Labeling of Chemicals was developed by the UN, and adopted by OSHA in 2012, to ensure the safe production, transport, handling, use and disposal of hazardous materials. The system provides a simplified approach of communicating hazards in a uniform way through the use of 9 pictograms, 2 signal words, 72 hazard statements and 116 precautionary statements.

Labels

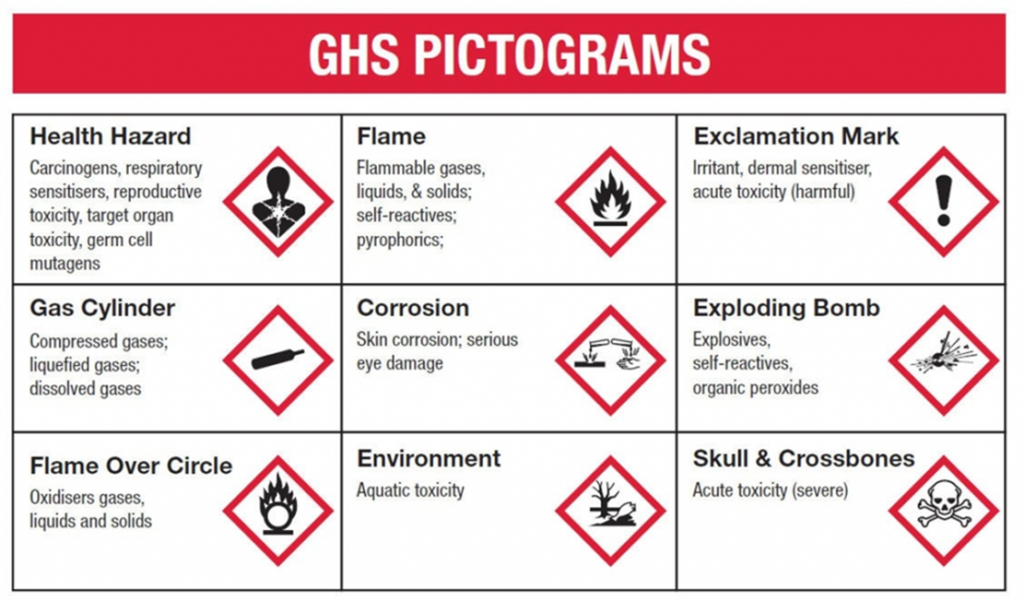

Chemical manufacturers are required to use the GHS labeling system for the primary chemical container labels. There are six elements required in a GHS label:

- The signal word ‘Danger’ or ‘Warning’ indicating the hazard level

- Applicable GHS pictograms

- Manufacturer information

- Precautionary statements describing general preventative, response, storage or disposal precautions

- Hazard statements that describe the nature of the hazardous products and the degree of hazard

- Product name

Safety Data Sheets

The Hazard Communication Standard requires chemical manufacturers, distributors, or importers to provide Safety Data Sheets (SDSs) (formerly known as Material Safety Data Sheets or MSDSs) to communicate the hazards of hazardous chemical products. OSHA’s Occupational Exposure to Hazardous Chemicals in Laboratories states that employers must provide the “location and availability of known reference material on the hazards, safe handling, storage and disposal of hazardous chemicals found in the laboratory including, but not limited to, safety data sheets received from the chemical supplier.”

Supervisors must review SDSs for chemicals/products used in the workplace to determine if control measures and personal protective equipment (PPE) are needed.

SDSs must be readily available to all personnel working with hazardous chemicals.

Personal Protective Equipment (PPE)

The PI or laboratory supervisor must determine the required PPE by conducting a hazard assessment and the department or supervisor shall provide all necessary PPE as identified in the assessment.

PPE is not a substitute for engineering or administrative controls, or good work practices, but should be used in conjunction with these controls.

The completed hazard assessment in LATCH will identify the minimum PPE required for each activity. The lab may modify the PPE as needed based on the risk of the activity.

Training shall be provided by the supervisor or a qualified designee prior to the employee working in an area requiring the use of PPE.